Your session has timed out. Please log in again

Surpassing the high productivity of the previous model, tool change speed and acceleration have been enhanced to acquire overwhelming speed normally only achieved by a compact machine.

Cycle time 15% DOWN (compared to previous model)

* Data taken while running machining program created by Brother

Tool change time is greatly reduced by increasing the arm’s swivel speed and reducing any waste time.

| Tool to Tool |

|---|

|

| Chip to Chip |

|---|

|

Acceleration of the Z-axis during frequent operation is dramatically improved. In addition to this, vibration is reduced via vibration control.

| Z-axis acceleration |

|---|

|

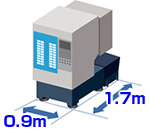

The machine depth has been reduced by approximately 100 mm while maintaining all strokes to further reduce the size from the previous compact model.

This allows you to use plant space more effectively.

| Installation space |

|---|

| 0.9m X 1.7m (including coolant tank) |

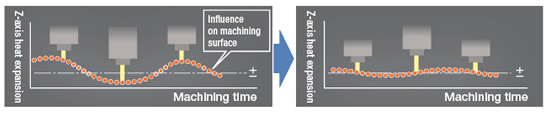

The machine uses a highly rigid column structure and a high-performance motor. The B00 series NC controller elicits machine performance, ensuring highly accurate, high quality machining. The machine is standard equipped with the heat expansion compensation system for the XYZ axes. The algorithm has been reviewed to enable more accurate machining compared to the previous model.

This system predicts the heat expansion based on the movement of each axis and compensates for it. As no sensors are used, machining time is not affected.

The machine is equipped with a B00 series CNC controller developed integrally with the machine, focusing on usability. Various user-friendly functions are available, such as the menu programming function, USB memory interface, and tool length range setting function. In addition to these, some new functions have been added, for example, the tap return function to assist tool recovery in the event of power failure.

Brother established the "Brother Green Label" in compliance with ISO International Standards and Japan Industrial Standards(JIS), and is striving for environment-friendly manufacturing. Air consumption, standby power, etc. have been reduced. LED lamps are used for the work light, saving energy and providing longer life.

(Photo is LED type work light.)

|

|

|

|---|---|---|

| TC-S2DN/-O/-S | TC-22B/TC-22B-O | TC-20B |

|

|

|

|

|

|

|

|---|---|---|

| TC-R2B | TC-32BN QT/FT | TC-31B |

|

|

|

|