Your session has timed out. Please log in again

SPEEDIO

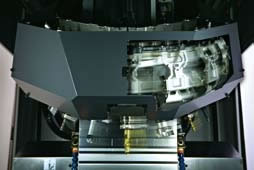

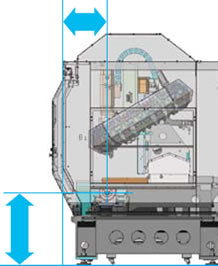

High-speed tool change is possible due to the turret magazine being mounted around the column. Up to 22 tools can be stored.

The newly developed high-speed and high-output built-in DD motor produces more efficient turning. The maximum speed is 2,000 min-1.

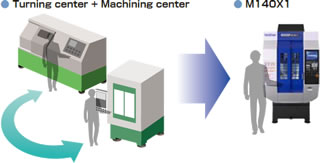

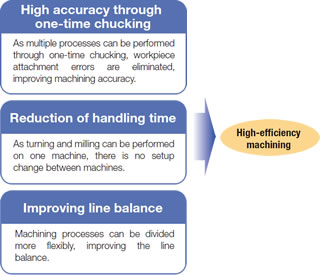

Workpieces previously machined using a turning center and a machining center can now be machined on one machine with machining processes integrated. This reduces handling time between machines.

Integration of the turning process and milling process brings various advantages, and contributes to high-efficiency machining expected by customers.

Using a fast acceleration/deceleration spindle motor and highly-responsive servo control achieves quicker starting and stopping of the spindle.

| Start/stop time |

|---|

| 0.2s |

High-speed tool change achieved by optimal control for spindle start/stop, Z-axis up/down, and magazine operation.

| Chip to Chip |

|---|

| 1.4s |

As the spindle torque is high in the medium- and high-speed range, the machine fully demonstrates its capabilities in high-speed, high-efficiency machining for aluminum or steel.

| Max. torque |

|---|

| 40Nm |

| Max. output |

|---|

| 18.9kW |

The machine provides excellent turning capabilities due to the high-output turning spindle and the double plunger lock for the turning tool. The time taken for the turning spindle to reach the maximum speed of 2,000 min-1 is 0.3 seconds or less, leading to reduction in machining time.

| Max. torque |

|---|

| 55Nm |

| Max. output |

|---|

| 8.7kW |

The turning spindle table is at a position where the operator can change workpieces comfortably in a natural posture.

| From front opening to table |

|---|

| 490mm |

| From floor to table |

|---|

| 795mm |

The machine is equipped with the new CNC-C00 controller, greatly improving processing capabilities and enhancing functions and usability.

Equipped with 'shortcut' keys to quickly open the desired screen and 'sub folder' to make program management easier, in addition to the USB memory interface, menu programming and tap return function.

High capacity program data can be transferred via Ethernet at high speed. The simple production monitoring function is also available allowing you to monitor the machine's status.

Equipped with machining support functions, such as torque waveform display,high accuracy mode, and heat expansion compensation system.

Equipped with motor insulation resistance measurement, operation log, and maintenance notice function.

Standard equipped with PLC. Input and output points can be extended to up to 1024 points each ( Optional ).

|

|

|

|

|

|---|---|---|---|---|

| S300X1/S500X1/S700X1 | S1000X1 | M140X1 | R450X1 | R650X1 |

|

|

|

|

|

|

|

|---|

| TC-32BN QT/FT |

|

|