Your session has timed out. Please log in again

SPEEDIO

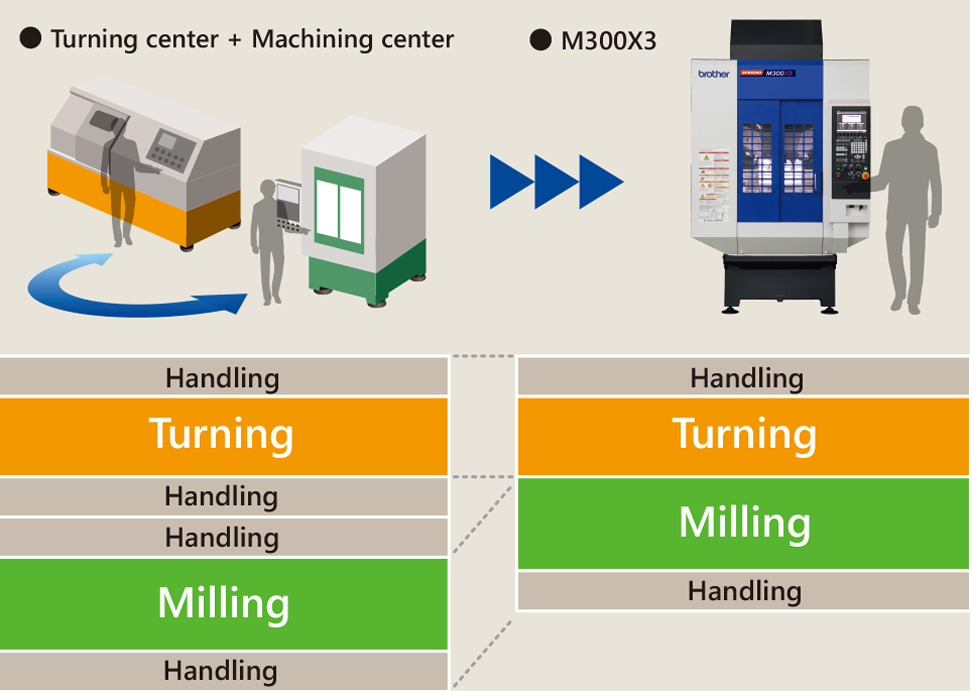

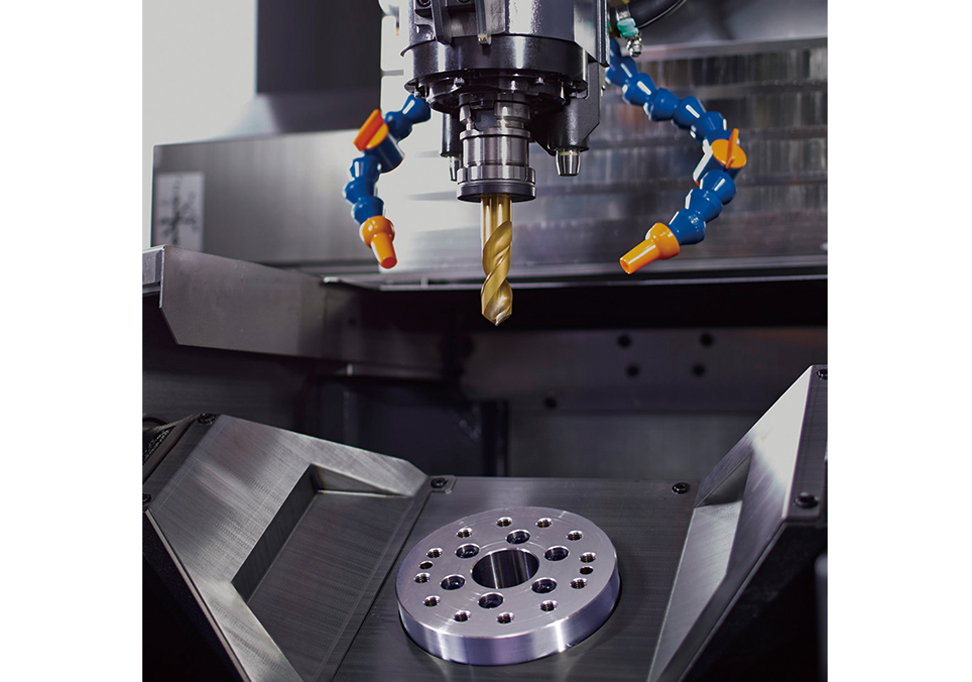

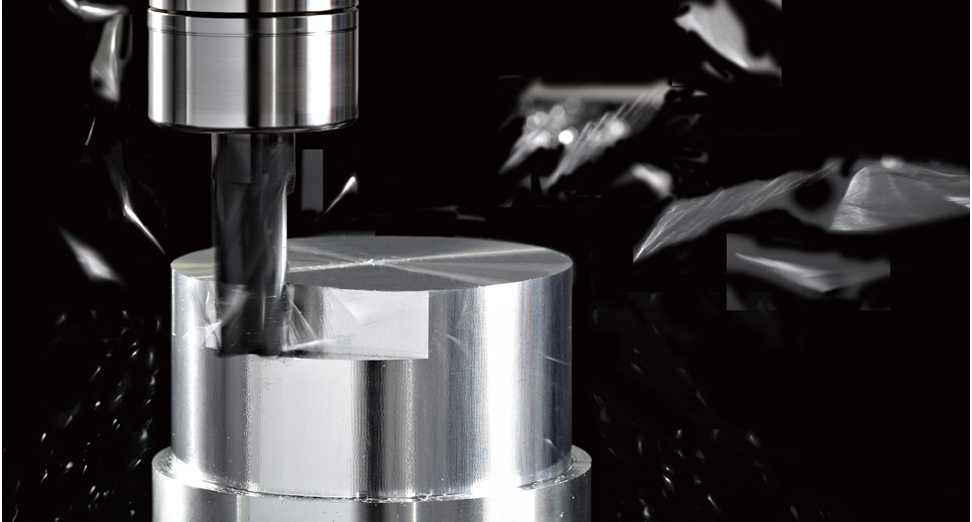

Workpieces previously machined using a turning center and a machining center can now be machined on one machine with machining processes integrated. This reduces handling time between machines.

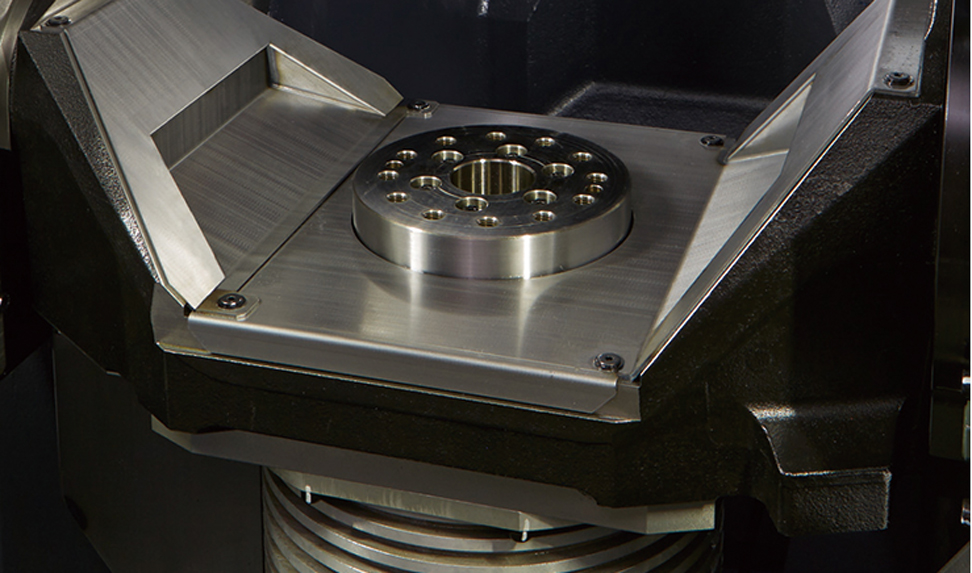

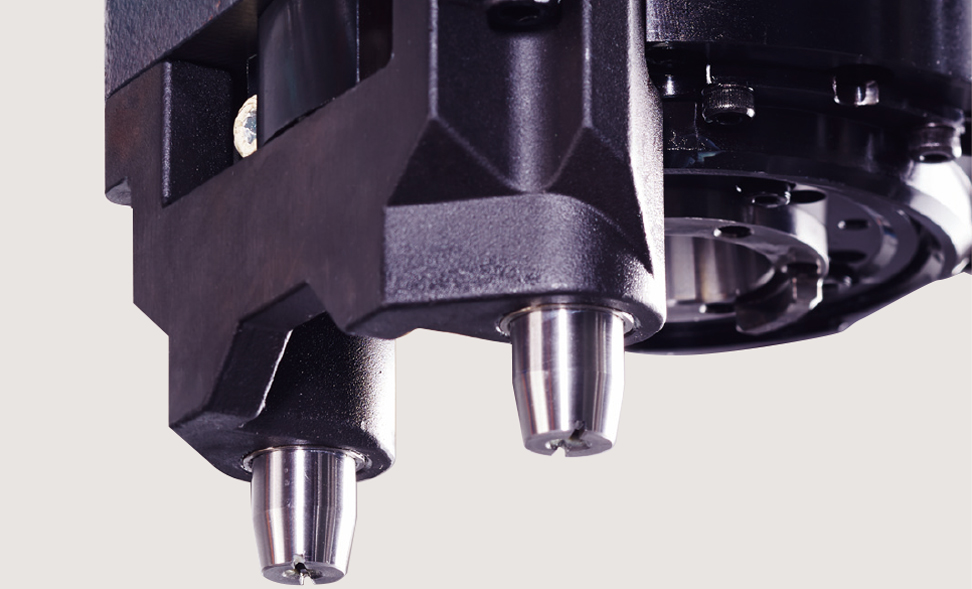

Machining capabilities and accuracy have been improved by increasing the rigidity of the tilt axis and turning spindle, and improving the balance of rigidity over the previous model. A double plunger lock, with a reputation for stable machining, is used to secure the turning tool.

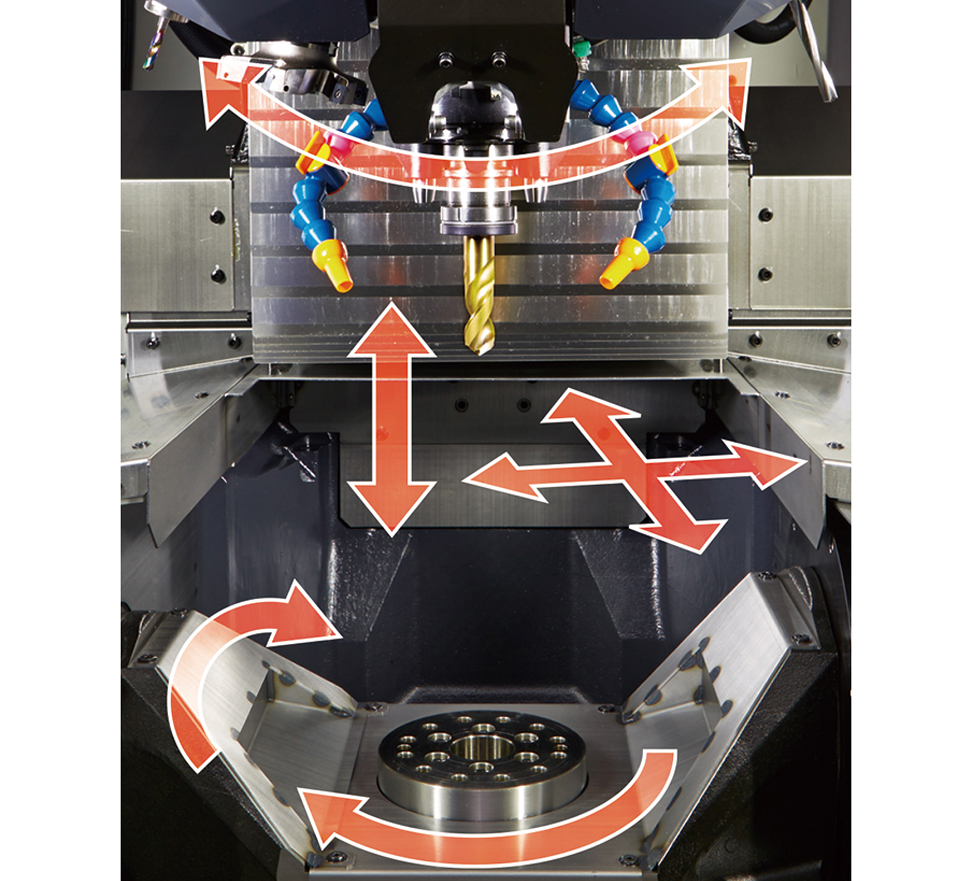

A roller gear is used for the tilt axis (A-axis). This backlashless gear achieves high-accuracy machining and the clampless structure enables high-speed indexing.

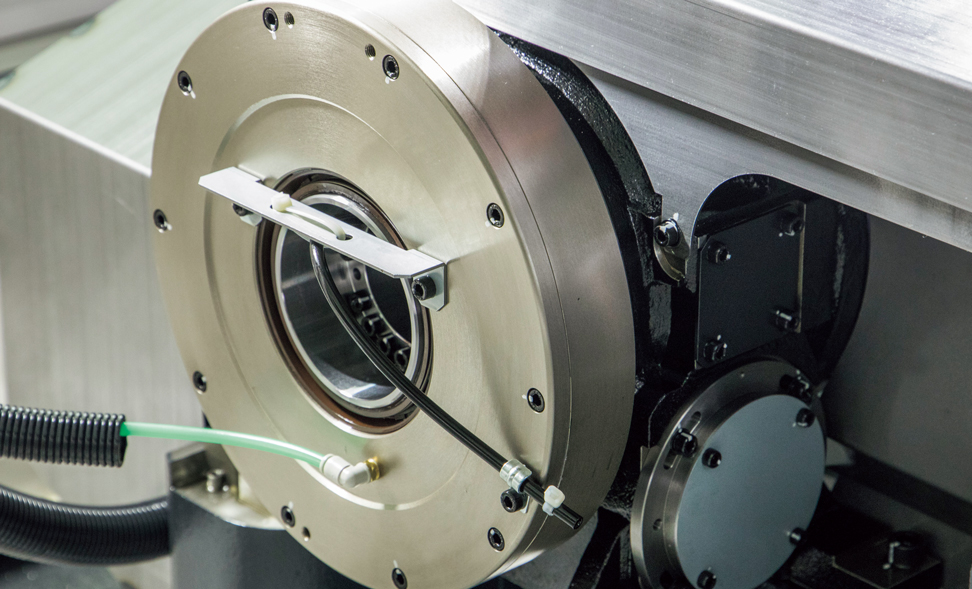

A high-speed and high-output built-in DD motor is used for the turning spindle (C-axis). The turning spindle is applied in three modes: indexing table, turning and cutting feed.

An original double plunger lock is used to achieve excellent tool change repeatability and high machining capabilities when turning tools are attached.

Using a fast acceleration / deceleration spindle motor and highly-responsive servo control achieves quicker starting and stopping of the spindle and turning spindle.

| Start / stop time |

|---|

| Spindle : 0.2s Turning spindle : 0.3s |

Using a compact 22-tool magazine with excellent weight balance and optimal control achieves high-speed tool change, with any wasted operation eliminated.

| Chip-Chip : 1.4s Tool-Tool : 0.9s |

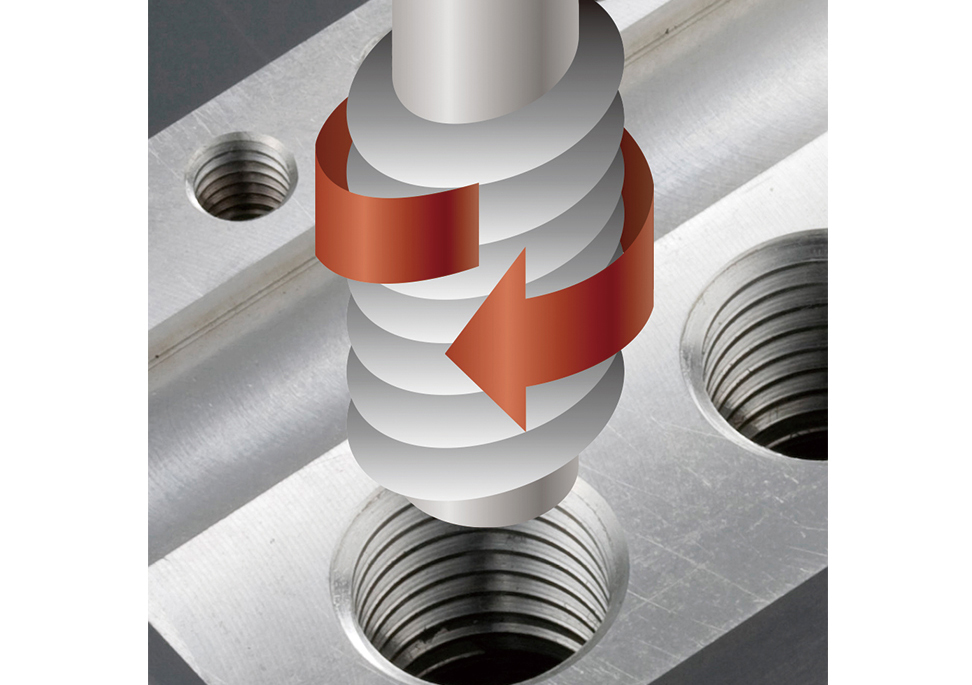

Original synchronized tapping control enables high-accuracy tapping at the fastest level in the world.

| Peripheral speed : 377m/min |

Wasted time is further reduced by positioning the X/Y/Z axes and A/C axes simultaneously with tool changes.

| Reduction in non-cutting time |

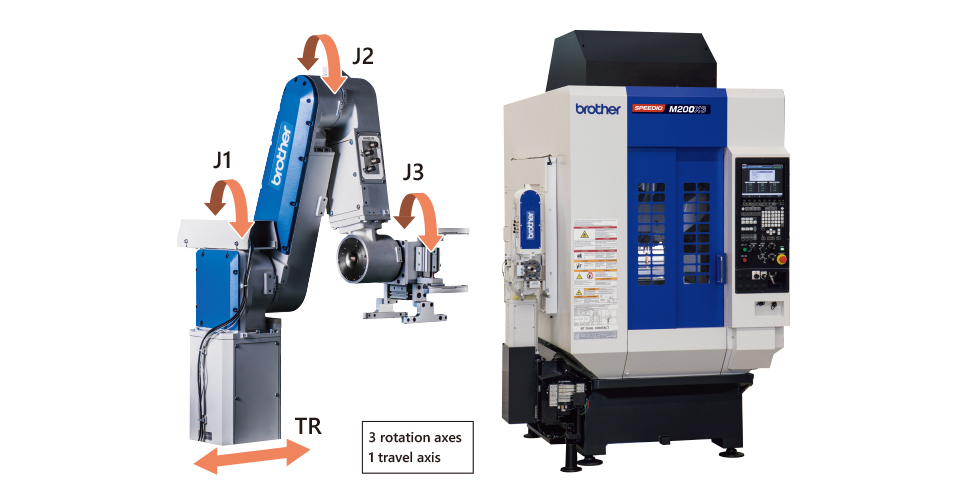

Simple, compact, and easy installation/startup

As the spindle can provide high torque even in the medium- and high-speed range, the machine fully demonstrates its capabilities in high-speed, high-efficiency machining of aluminum or steel.

| Max. torque : 40Nm Max. output : 18.9kW |

High-efficiency machining is achieved by the high-output turning spindle with a maximum speed of 2,000 min-1, and the turning tool secured by the double plunger lock.

| Max. torque : 55Nm Max. output : 8.7kW |

Chip discharge performance and handling capability have been improved along with the expansion of the machine area. In addition, the machine is equipped with functions to improve reliability, such as chip shower and air-assisted tool washing.

The machine is equipped with our original �CNC-C00 Series� controller, created through machine/controller integrated development.

Equipped with tool monitoring functions

|

|

|

|

|

|---|---|---|---|---|

| S300X1/S500X1/S700X1 | S1000X1 | M140X2 | R450X1 | R650X1 |

|

|

|

|

|

|

|

|---|

| TC-32BN QT/FT |

|

|